Questions & Answers

Looking for some solutions for your bunkers?

This is a great place to start!

Why was the Bunker Solution system developed?

Bunker Solution was developed after installing and testing most commercially available liners and not finding a solution to the problem. After experiencing other liner failures, Kevin Clark defined the comprehensive needs and requirements of a liner as the following essential principles: keep the sand clean, reduce the movement of the sand, facilitate drainage and stand up over time.

Why is the Bunker Solution system better than other liners?

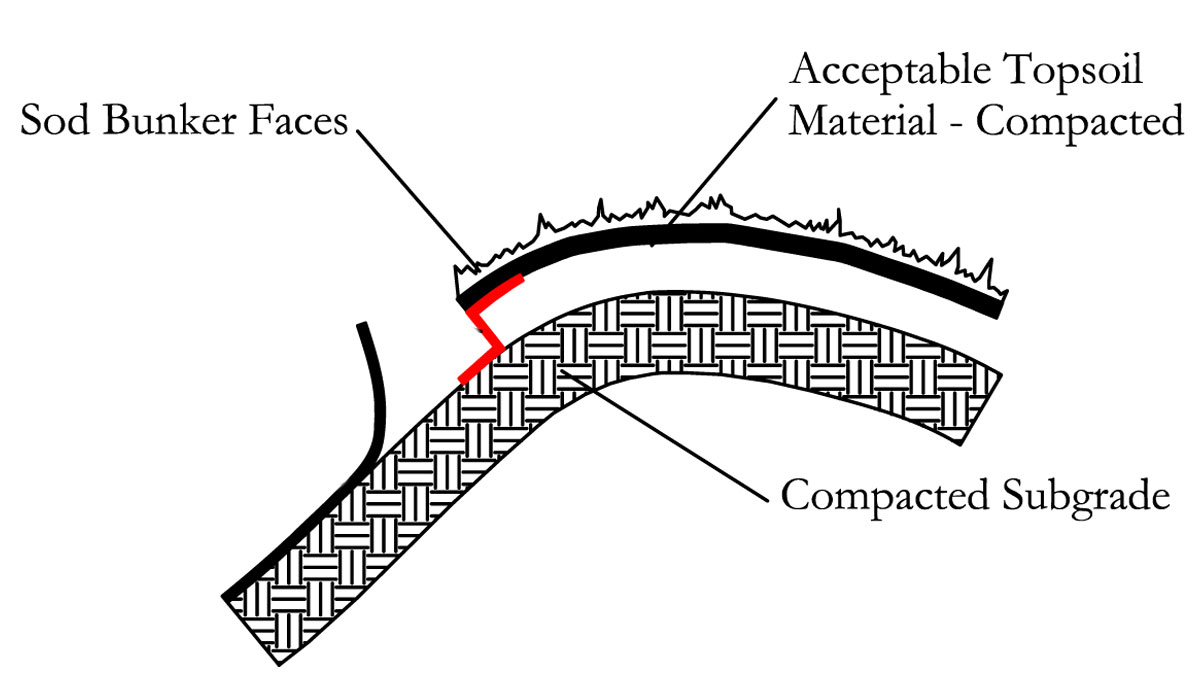

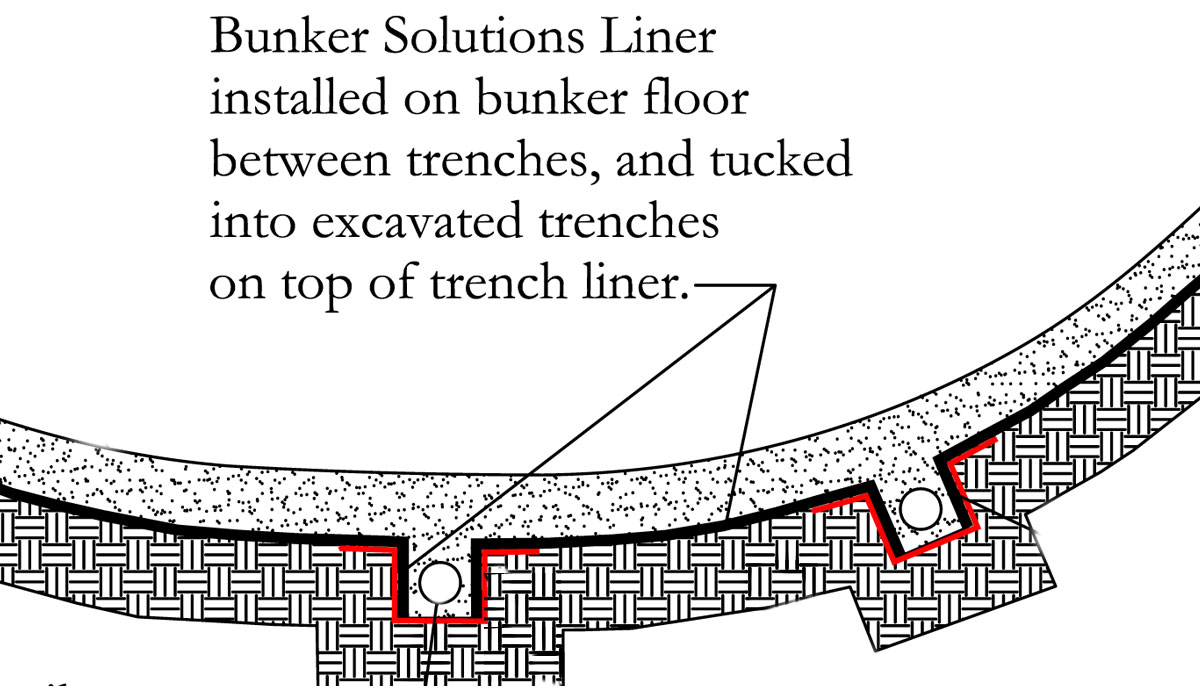

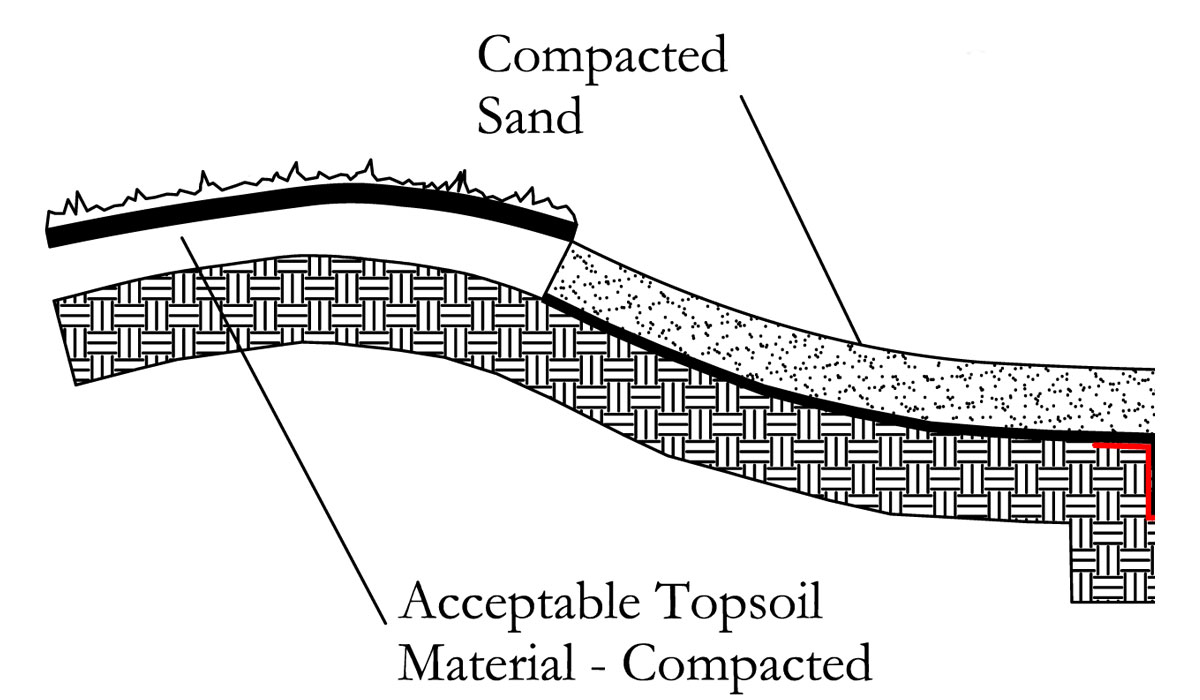

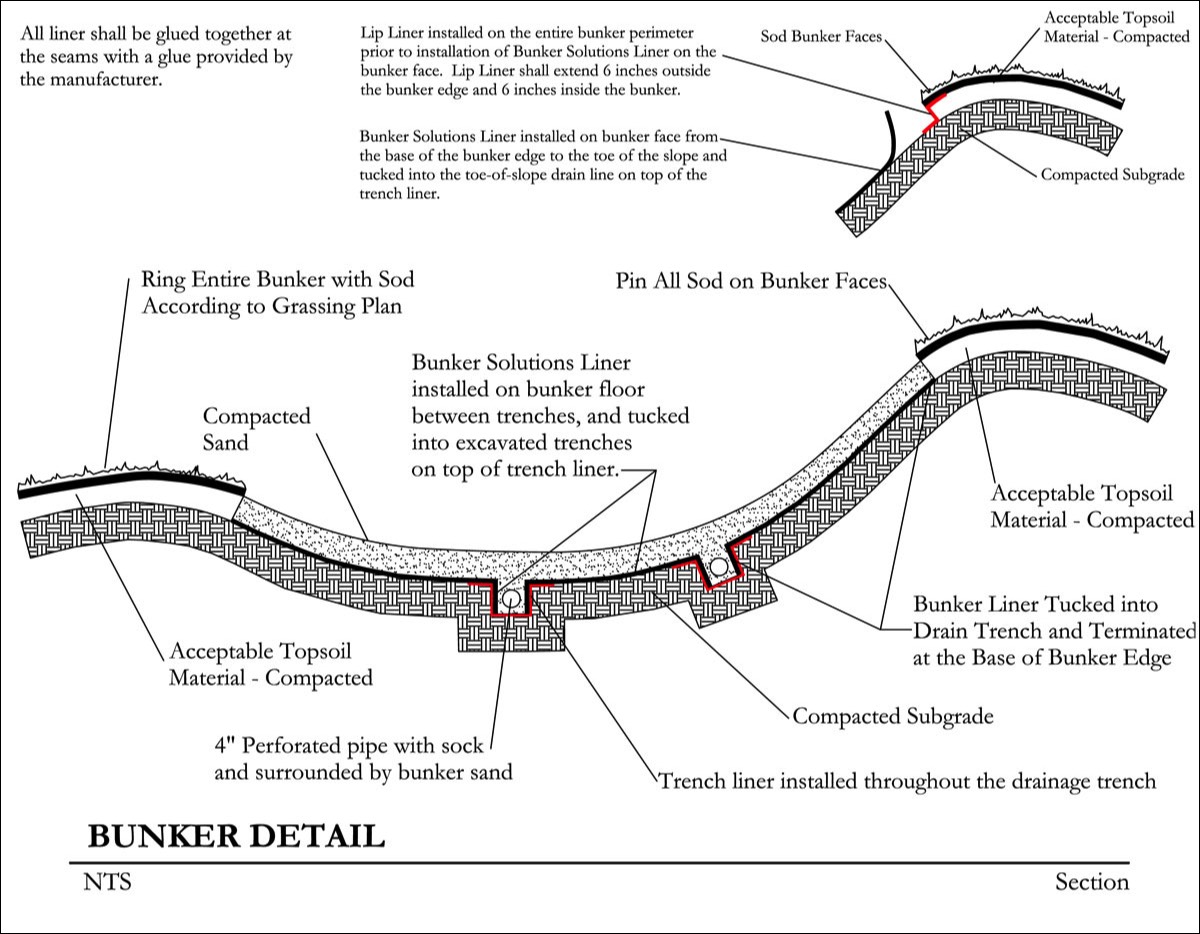

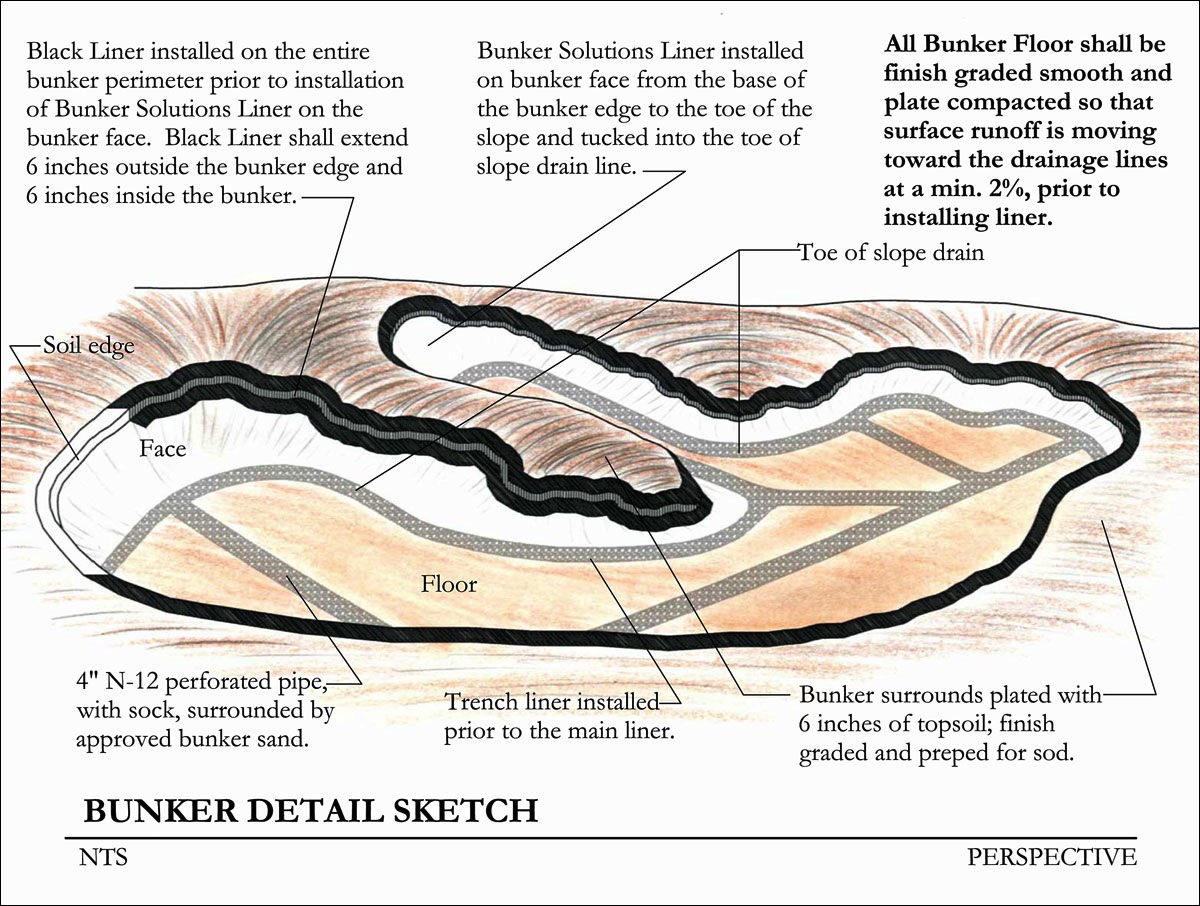

The Bunker Solution system is designed to specifically address problems associated with bunker maintenance using three components: a geo-textile anchor, an impermeable ditch liner, and an engineered mat. Together, these components form a complete system providing a patented solution to the problems.

Is the Bunker Solution system covered under a warranty?

Yes. The Bunker Solution mat is backed by a fifteen-year manufacturer’s repair / replacement warranty.

How is the product sold?

All materials are sold directly to the club, contractor or client.

The engineered mat is sold by the square foot.

The lip and drainage liners are sold by the linear foot.

The engineered mat is sold by the square foot.

The lip and drainage liners are sold by the linear foot.

Do I need to line the entire bunker?

It is highly recommended to line the entire bunker. Bunker Solution is designed as a three-part system. Lining the entire bunker with the engineered mat preserves the integrity of the system and is necessary to achieve the desired functionality.

Does the ditch liner cover the entire bunker shell?

No. The ditch liner is installed in the drainage ditch and extends slightly on both sides of the ditch.

In which direction is the mat installed?

In the body of the bunker, the engineered mat is installed with the grain facing in the direction of the target. On the bunker faces, the mat is installed with the grain pointing up the slope.

How do I maintain the edge / lip?

With a string trimmer. The Bunker Solution system is designed to stand up to the rigors of string trimmers and eliminates the need for special equipment.

What is the recommended spacing of mechanical fasteners?

Spacing will vary depending upon the complexity of the bunker design, the consistency of the substrate, and the climate of the area. A general rule of thumb is spacing of twelve to sixteen inches in the field and four inch spacing on the seams and lips.

Will my drainage pipe clog?

No. The use of a socked pipe in a pure sand environment prevents the pipe from clogging.

What measurements do I need?

There are three critical measurements needed to determine the amount of material needed:

- linear feet of bunker perimeters

- linear feet of drainage

- total square footage of bunker(s)

Bunker Solution: Developed by a Superintendent for the Superintendent

info@bunkersolution.com

214-564-4478 or 469-799-5413